Black & Decker CD115 Angle Grinder

Introduction

For jobs involving cutting, grinding, and polishing, the Black & Decker CD115 Angle Grinder is a strong and adaptable instrument. This angle grinder’s ergonomic handle, small size, and 710-watt motor make it perfect for both experts and do-it-yourselfers. It has a two-position side handle for improved control and a spindle lock for simple disc swaps. Whether you’re dealing with brick, stone, or metal, the CD115 offers accurate and dependable performance.

Specification

- 710 watts is the power rating.

- The disc measures 115 mm, or 4.5 inches.

- Ten thousand revolutions per minute is the no-load speed.

- M14 (metric thread) is the spindle thread size.

- Features for safety include an adjustable safety guard. For simple disk changes, use a spindle lock.

- For improved comfort and control, use the two-position side handle.

- About 1.9 kg (4.2 lbs) in weight.

- The length of the cable is 2.5 meters (8.2 feet).

- Small size for convenient handling.

Intended use

Your Black & Decker angle grinder has been designed for cutting metal and masonry using the appropriate type of cutting or grinding disc.This tool is intended for consumer use only.

Feature

- Offers strong performance for activities involving cutting and grinding.

- Suitable for a variety of grinding and cutting discs.

- Simple and secure disc replacement.

- The user is shielded from debris by the adjustable safety guard.

- A two-position side handle improves comfort and control when in use.

- Simple to manage and control.

Safety instructions

Warning! When using mains-powered tools, basic safety precautions, including the following, should always be followed to reduce the risk of fire, electric shock, personal injury and material damage.

- Read all of this manual carefully before operating the tool.

- Retain this manual for future reference.

- Remove the plug from the socket before carrying out any adjustment, servicing or maintenance.

Keep work area clean

Cluttered areas and benches can cause accidents.

Consider work area environment

- Do not expose the tool to rain.

- Do not use the tool in damp or wet conditions.

Keep the work area well lit.

- Do not use the tool where there is a risk of causing fire or explosion, e.g. in the presence of flammable liquids and gases.

- Keep children away Do not allow children, visitors or animals to come near the work area or to touch the tool or mains cable.

Dress properly

- Do not wear loose clothing or jewellery, as these can be caught in moving parts.

- Preferably wear rubber gloves and non-slip footwear when working outdoors.

- Wear protective hair covering to keep long hair out of the way.

Personal protection

- Always use safety glasses.

- Use a face or dust mask whenever the operations may produce dust or flying particles.

- Hearing protection should be worn.

Guard against electric shock

- Prevent body contact with earthed or grounded surfaces (e.g. pipes, radiators, cookers and refrigerators).

- Electric safety can be further improved by using a high-sensitivity (30 mA / 30 mS) residual current device (RCD).

Do not overreach

- Keep proper footing and balance at all times.

Stay alert

- Watch what you are doing. Use common sense.

- Do not operate the tool when you are tired.

Secure workpiece

- Use clamps or a vice to hold the workpiece.

- It is safer and it frees both hands to operate the tool.

Connect dust extraction equipment

- If devices are provided for the connection of dust extraction and collection facilities, ensure that these are connected and properly used.

Remove adjusting keys and wrenches

Always check that adjusting keys and wrenches are removed from the tool before operating the tool.

Extension cables

Before use, inspect the extension cable and replace if damaged. When using the tool outdoors, only use extension cables intended for outdoor use. Up to 30 m of Black & Decker extension cable can be used without loss of power.

Use appropriate tool

The intended use is described in this instruction manual. Do not force small tools or attachments to do the job of a heavy-duty tool. The tool will do the job better and safer at the rate for which it was intended. Do not force the tool. Do not use the tool for purposes not intended, for example, do not use a circular saw to cut tree limbs or logs.

Warning! The use of any accessory or attachment or performance of any operation with this tool other than those recommended in this instruction manual may present a risk of personal injury.

Check for damaged parts

Before use, carefully check the tool and mains cable for damage. Check for misalignment and seizure of moving parts, breakage of parts, damage to guards and switches and any other conditions that may affect its operation. Ensure that the tool will operate properly and perform its intended function. Do not use the tool if any part is damaged or defective. Do not use the tool if the switch does not turn it on and off. Have any damaged or defective parts repaired or replaced by an authorised repair agent. Never attempt any repairs yourself.

Unplug the tool

Unplug the tool when it is not in use, before changing any parts of the tool, accessories or attachments and before servicing.

Avoid unintentional starting

Do not carry the tool with a finger on the on/off switch. Be sure that the tool is switched off when plugging in.

Do not abuse cord

Never carry the tool by its cord or pull it to disconnect from the socket. Keep the cord away from heat, oil and sharp edges.

Store idle tools

When not in use, tools should be stored in a dry, locked up or high place, out of reach of children.

Maintain tools with care

Keep cutting tools sharp and clean for better and safer performance. Follow the instructions for maintenance and changing accessories. Keep handles and switches dry, clean and free from oil and grease.

Repairs

This tool complies with relevant safety requirements. Repairs should only be carried out by qualified persons using original spare parts; otherwise this may result in considerable danger to the user.

Electrical safety

This tool is double insulated; therefore no earth wire is required. Always check that the power supply corresponds to the voltage on the rating plate.

Additional safety instructions for Australia and New Zealand

- This appliance is not intended for use by young or infirm persons without supervision. Children must be supervised to ensure they do not play with the appliance.

- If the supply cord is damaged, it must be replaced by the manufacturer or an authorised Black & Decker Service Centre in order to avoid a hazard.

Additional safety instructions for angle grinders

Read the instruction manual before use.

Read the instruction manual before use. Wear safety glasses or goggles when operating this tool.

Wear safety glasses or goggles when operating this tool. Wear ear protection when operating this tool.

Wear ear protection when operating this tool.- Always use eye and ear protection when operating this tool.

- Personal protective equipment such as dust mask, gloves, helmet and apron should be worn.

- Do not cut or grind light metal with a magnesium content exceeding 80%, since this type of metal is flammable.

- Only use grinding and cutting discs and other accessories recommended in this manual.

- Make sure that the maximum speed of the grinding or cutting disc exceeds the no-load speed of the tool.

- Do not use grinding and cutting discs that do not conform to the dimensions stated in the technical data.

- Do not use separate reducing bushings or adapters or make unauthorised modifications to adapt large hole abrasive wheels.

- Do not cut workpieces requiring a maximum depth of cut exceeding that of the cutting disc.

- Do not use cutting discs for side grinding.

- Inspect grinding and cutting discs before each use.

- Do not use chipped, cracked or otherwise defective discs.

- Ensure that mounted wheels and points are fitted in accordance with the manufacturer’s instructions.

- Ensure that the abrasive product is correctly mounted and tightened before use and run the tool at no-load for 30 s in a safe position, stop immediately if there is considerable vibration or if other defects are detected

If this condition occurs, check the machine to determine the cause.

- Ensure that blotters are used when they are provided with the bonded abrasive product and when they are required.

- When applying a threaded hole disc, ensure that the thread is long enough to accept the spindle length.

- Never use the tool without the guard.

- Check that the workpiece is properly supported.

- Do not exert side pressure on the grinding or cutting disc.

- Ensure that sparks resulting from use do not create a hazard e.g. do not hit persons, or ignite flammable substances.

- Beware that after switching off the tool the wheel continues to rotate for a short period.

- Ensure that ventilation slots are kept clear when working in dusty conditions. If it should become necessary to clear dust, first disconnect the tool from the mains supply. Avoid damaging internal parts, use a soft brush or dry cloth, do not use metallic objects.

- Abrasive wheels shall be stored and handled with care in accordance with manufacturer’s instructions and always store grinding and cutting discs in a dry place.

Features

This tool includes some or all of the following features.

- On/off switch

- Side handle

- Spindle lock

- Guard

Assembly

Warning! Before assembly, make sure that the tool is switched off and unplugged.

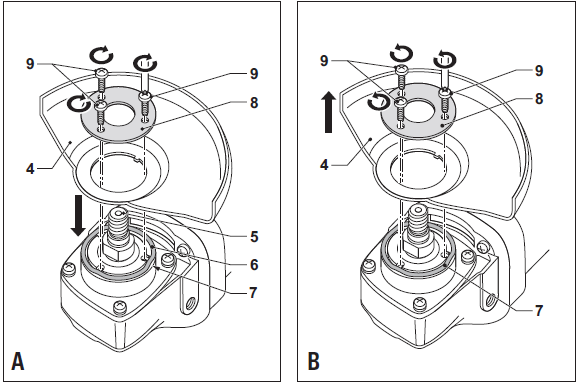

Fitting and removing the guard

- Place the tool on a table, with the spindle (5) facing up.

- Place the spring washer (6) over the spindle and locate it on the shoulder (7).

- Place the guard (4) onto the tool as shown.

- Place the flange (8) over the spindle with the protruding pips towards the guard. Make sure that the holes in the flange align with the screw holes.

- Secure the flange with the screws (9). Make sure that the screws are fully tight and that the guard can be rotated. Removing

- Use a screwdriver to remove the screws (9).

- Remove the flange (8), guard (4) and spring washer (7). Store these parts carefully.

Warning! Never use the tool without the guard.

Fitting the side handle

- Screw the side handle (2) into one of the mounting holes in the tool.

Warning! Always use the side handle. Fitting and removing grinding or cutting discs Always use the correct type of disc for your application. Always use discs with the correct diameter and bore size (see technical data).

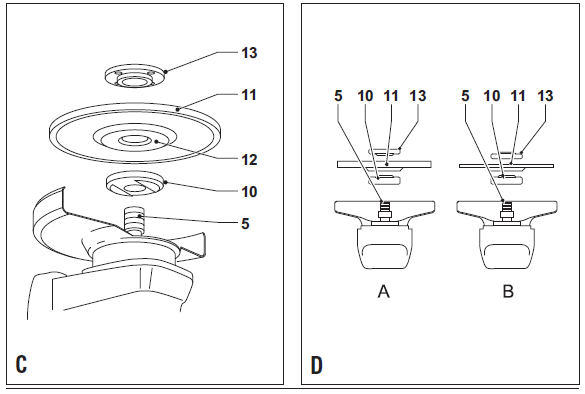

- Fit the guard as described above.

- Place the inner flange (10) onto the spindle (5) as shown . Make sure that the flange is correctly located on the flat sides of the spindle.

- Place the disc (11) onto the spindle (5) as shown If the disc has a raised centre (12), make sure that the raised centre faces the inner flange.

- Make sure that the disc locates correctly on the inner flange.

- Place the outer flange (13) onto the spindle. When fitting a grinding disc, the raised centre on the outer flange must face towards the disc When fitting a cutting disc, the raised centre on the outer flange must face away from the disc

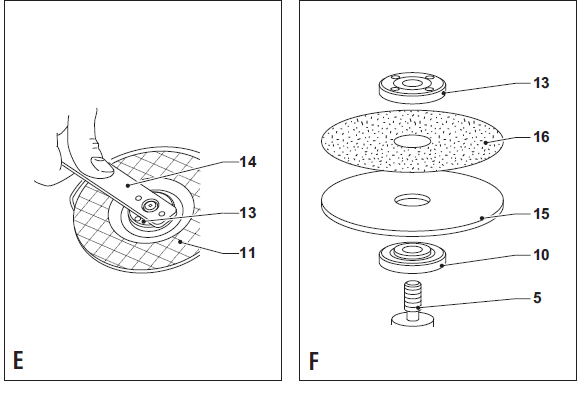

- Keep the spindle lock (3) depressed and tighten the outer flange using the two-pin spanner (14)

- Keep the spindle lock (3) depressed and loosen the outer flange (13) using the two-pin spanner (14)

- Remove the outer flange (13) and the disc (11). Fitting and removing sanding discs For sanding, a backing pad is required. The backing pad is available from your Black & Decker dealer as an accessory.

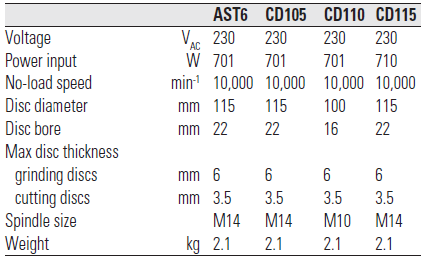

- place the inner flange (10) onto the spindle (5) Make sure that the flange is correctly located on the flat sides of the spindle.

- Place the backing pad (15) onto the spindle.

- Place the sanding disc (16) onto the backing pad.

- Place the outer flange (13) onto the spindle with the raised centre facing away from the disc.

- Keep the spindle lock (3) depressed and tighten the outer flange using the two-pin spanner (14)

- Make sure that the outer flange is fitted correctly and that the disc is clamped tightly.

Removing

- Keep the spindle lock (3) depressed and loosen the outer flange (13) using the two-pin spanner (14)

- Remove the outer flange (13), the sanding disc (16) and the backing pad (15).

- Use Warning! Let the tool work at its own pace. Do not overload.

- Carefully guide the cable in order to avoid accidentally cutting it.

- Be prepared for a stream of sparks when the grinding or cutting disc touches the workpiece.

- Always position the tool in such a way that the guard provides optimum protection from the grinding or cutting disc. Switching on and off

- To switch on, slide the on/off switch (1) forward. Note that the tool will continue running when you release the switch.

- To switch off, press the rear part of the on/off switch. Warning! Do not switch the tool off while under load.

Hints for optimum use

- Firmly hold the tool with one hand around the side handle and the other hand around the main handle.

- When grinding, always maintain an angle of approx. 15° between the disc and the workpiece surface.

- Maintenance Your tool has been designed to operate over a long period of time with a minimum of maintenance.

- Continuous satisfactory operation depends upon proper tool care and regular cleaning.

Warning! Before performing any maintenance, switch off and unplug the tool.

- Regularly clean the ventilation slots in your tool using a soft brush or dry cloth.

- Regularly clean the motor housing using a damp cloth. Do not use any abrasive or solvent-based cleaner.

- Mains plug replacement (U.K. & Ireland only) If a new mains plug needs to be fitted:

- Safely dispose of the old plug.

- Connect the brown lead to the live terminal in the new plug.

- Connect the blue lead to the neutral terminal.

Warning! No connection is to be made to the earth terminal.

Protecting the environment

Separate collection. This product must not be disposed of with normal household waste. Should you find one day that your Black & Decker product needs replacement, or if it is of no further use to you, do not dispose of it with household waste. Make this product available for separate collection.

Separate collection of used products and packaging allows materials to be recycled and used again. Re-use of recycled materials helps prevent environmental pollution and reduces the demand for raw materials.

Local regulations may provide for separate collection of electrical products from the household, at municipal waste sites or by the retailer when you purchase a new product.

Black & Decker provides a facility for the collection and recycling of Black & Decker products once they have reached the end of their working life. To take advantage of this service please return your product to any authorised repair agent who will collect them on our behalf.

You can check the location of your nearest authorised repair agent by contacting your local Black & Decker office at the address indicated in this manual. Alternatively, a list of authorised Black & Decker repair agents and full details of our after-sales service and contacts are available on the Internet at: www.2helpU.com

Technical data

EC declaration of conformity

AST6/CD105/CD110/CD115 Black & Decker declares that these products conform to: 98/37/EC, 89/336/EEC, EN 50144, EN 55014, EN 61000 LpA (sound pressure) 89.9 dB(A), LWA (acoustic power) 102.9 dB(A), hand/arm weighted vibration < 2.5 m/s2

- Kevin Hewitt

- Director of Consumer Engineering

- Spennymoor, County Durham DL16 6JG,

- United Kingdom

- 1-5-2005

Guarantee

Black & Decker is confident of the quality of its products and offers an outstanding guarantee. This guarantee statement is in addition to and in no way prejudices your statutory rights. The guarantee is valid within the territories of the Member States of the European Union and the European Free Trade Area. If a Black & Decker product becomes defective due to faulty materials, workmanship or lack of conformity, within 24 months from the date of purchase, Black & Decker guarantees to replace defective parts, repair products subjected to fair wear and tear or replace such products to ensure minimum inconvenience to the customer unless:

- The product has been used for trade, professional or hire purposes;

- The product has been subjected to misuse or neglect;

- The product has sustained damage through foreign objects, substances or accidents;

- Repairs have been attempted by persons other than authorised repair agents or Black & Decker service staff.

To claim on the guarantee, you will need to submit proof of purchase to the seller or an authorised repair agent. You can check the location of your nearest authorised repair agent by contacting your local Black & Decker office at the address indicated in this manual. Alternatively, a list of authorised Black & Decker repair agents and full details of our after-sales service and contacts are available on the Internet at: www.2helpU.com Please visit our website www.blackanddecker.co.uk to register your new Black & Decker product and to be kept up to date on new products and special offers. Further information on the Black & Decker brand and our range of products is available at www.blackanddecker.co.uk

Black & Decker

Australia

- Black & Decker (Australia) Pty. Ltd. Tel. 03-8720 5100

- 20 Fletcher Road, Mooroolbark, Fax 03-9727 5940

- Victoria, 3138

New Zealand

- Black & Decker Tel. 09 579 7600

- 81 Hugo Johnston Drive Fax 09 579 8200

- Penrose, Auckland, New Zealand

United Kingdom

- Black & Decker Tel. 01753 511234

- 210 Bath Road Fax 01753 551155

- Slough, Berkshire SL1 3YD Helpline 01753 574277

Black & Decker CD115 Angle Grinder Instruction Manual

FAQs

What is the CD115 angle grinder’s power rating?

Its 710-watt motor offers sufficient power for operations like cutting and grinding.

What disc size is used by the CD115?

It makes use of commonly accessible 115mm (4.5-inch) discs.

Is there a spindle lock on the CD115?

Indeed, it has a spindle lock for secure and simple disc replacements.

Is it possible to use the CD115 to cut metal?

Yes, it can cut through stone, brick, and metal if the right cutting disc is used.

Is there a safety guard on the CD115?

Indeed, it has a safety guard that can be adjusted to shield the user from flying debris.