Black & Decker QS900 Palm Grip Sander

Introduction

Small to medium-sized surfaces can be easily sanded with the Black & Decker QS900 Palm Grip Sander, a portable and multipurpose power tool. It is perfect for both professionals and do-it-yourselfers because of its ergonomic palm grip design, which guarantees comfort and control during prolonged use. To keep your workstation tidy, the QS900 has a 1.5-amp motor, variable speed control, and a dust collection system. Whether you’re dealing with plastic, metal, or wood, this sander produces results that are efficient and smooth.

General Safety Rules

WARNING: Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

- Keep work area clean and well lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

- Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

- Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable for out-door use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

- If operating a power tool in a damp location is unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

Personal Safety

- Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equip-ment such as dust mask, nonskid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off position before connecting to power source and/ or battery pack, picking up or carrying the tool.

- Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury. Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

Power tool use and care

- Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

- Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation.

- If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

- Use the power tool, accessories and tool bits, etc. in accordance with these instructions, taking into account the working conditions and the work to be performed.

- Use of the power tool for operations different from those intended could result in a hazardous situation.

Battery tool use and care

- Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

- U se power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

- When battery pack is not in use, keep it away from other metal objects like paper clips, coins, keys, nails, screws, or other small metal objects that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

- Under abusive conditions, liquid may be ejected from the battery, avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

Service

Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Specific Safety Rules

Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will also make exposed metal parts of the tool “live” and shock the operator.

WARNING: ALWAYS use safety glasses. E veryday eye glasses are NOT safety glasses. Also use face or dust mask if operation is dusty. ALWAYS WEAR

CERTIFIED SAFETY EQUIPMENT:

- ANSI Z87.1 eye protection (CAN/CSA Z94.3)

- ANSI S12.6 (S3.19) hearing protection

- NIOSH/OSHA/MSHA respiratory protection

- Sanding of lead-based paint is not recommended. See Sanding Lead Based Paint for additional information before sanding paint.

- Clean your tool out periodically.

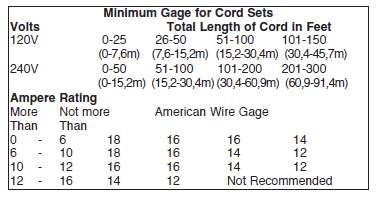

Extension Cords

When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The following table shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

The label on your tool may include the following symbols.

- V………………………. volts A…………………….. amperes

- Hz…………………….. hertz W……………………. watts

- min……………………. minutes ……………………alternating current

- ………………….. direct current no…………………… no load speed

- ……………………… Class II Construction ……………………. earthing terminal

- …………………….. safety alert symbol …/min……………….revolutions or reciprocations per minute

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

- lead from lead-based paints,

- crystalline silica from bricks and cement and other masonry products, and

- arsenic and chromium from chemically-treated lumber.

- Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

- Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

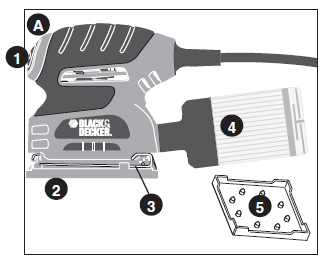

Functional Description

- On/Off Switch

- Sanding Pad

- Paper Clamp

- Dust Canister H ousing with F ilter

- Paper Punch

Safety Warnings and Instructions: Sanders

- ALWAYS USE PROPER EYE and respiratory PROTECTION.

- Clean your tool out periodically.

- Other Important Safety Warnings and Instructions

Sanding

- Sanding Lead based Paint

- Sanding of lead based paint is NOT RECOMM ENDED due to the difficulty of controlling the contaminated dust. The greatest danger of lead poisoning is to children and pregnant

women. - Since it is difficult to identify whether or not a paint contains lead without a chemical analysis, we recommend the following precautions when sanding any paint:

PERSONAL SAFETY

- No children or pregnant women should enter the work area where the paint sanding is being done until all clean up is completed.

- A dust mask or respirator should be worn by all persons entering the work area. The filter should be replaced daily or whenever the wearer has difficulty breathing.

NOTE: Only those dust masks suitable for working with lead paint dust and fumes should be used. Ordinary painting masks do not offer this protection. See your local hardware dealer for the proper (NIOSH approved) mask.

- NO EATING, DRINKING or SMOKING should be done in the work area to prevent ingesting contaminated paint particles. Workers should wash and clean up B EFORE eating, drinking or smoking. Articles of food, drink, or smoking should not be left in the work area where dust would settle on them.

ENVIRONMENTAL SAFETY

- Paint should be removed in such a manner as to minimize the amount of dust generated.

- Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils thickness.

- Sanding should be done in a manner to reduce tracking of paint dust outside the work area.

CLEANING AND DISPOSAL

- All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the duration of the sanding project. Vacuum filter bags should be changed frequently.

- Plastic drop cloths should be gathered up and disposed of along with any dust chips or other removal debris.

- They should be placed in sealed refuse receptacles and disposed of through regular trash pick-up procedures.

- During clean up, children and pregnant women should be kept away from the immediate work area.

- All toys, washable furniture and utensils used by children should be washed thoroughly before being used again.

Motor

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means your tool will operate on standard 60 H z household power. Do not operate AC tools on DC. A rating of 120 volts AC/DC means that you tool will operate on standard 60 H z AC or DC power. This information is printed on the nameplate. Lower voltage will cause loss of power and can result in over-heating. All B lack & Decker tools are factory-tested; if this tool does not operate, check the power supply.

Assembly/Adjustment Set-Up

CAUTION: To reduce the risk of injury, turn off and unplug the tool before making any adjustments or removing or installing attachments or accessories. attaching 1/4 sheet sandpaper

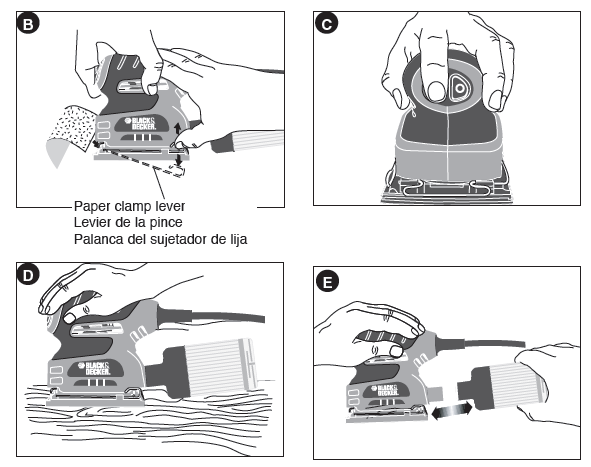

- Lift clamps up with your thumb,. Rotate the clamp lever downward until the clamp is fully opened.

- Lay sandpaper on a flat surface and, centering the pad of the unit, press the sander down firmly onto the paper.

- Wrap ends of the sandpaper around ends of the sander pad and clamp them in place using the clamps.

- To close clamps, rotate clamp handles back up as far as they will go and lock them in place.

- Stretch sandpaper as tight as possible when clamping.

NOTE

- On new tools the sandpaper may be difficult to install because of the stiffness of the sanding pad.

- This condition will improve as the pad compresses over time.

Punching sanding sheets

The paper punch is used for punching dust extraction holes in sanding sheets without pre-punched holes.

Attach a sanding sheet.

- Hold the tool in position directly above the paper punch.

- Press the tool with the sanding base down into the paper punch.

- Take the tool off the paper punch and check whether the holes in the sanding sheet have been fully pierced.

Operating Instructions

Warning: To reduce the risk of injury, let the tool work at its own pace. Do not overload.

WARNING: Shock hazard. Under no circumstances should this product be used near water.

Switch

- To turn the tool ON, hold it as shown in figure C and push the portion of the switch marked

- “I”. To turn the tool off, push the portion of the switch marked “O”.

Operation

Grasp the sander as shown in figure D and turn it ON. Move it in long, sweeping strokes along the surface, letting it do the work. Pushing down on the tool while sanding actually slows the removal rate and produces an inferior quality finish. Check your work often. Sander is capable of removing material rapidly especially with coarse paper. dust CANISTER

Attaching and removing:

Fit the dust canister over the dust extraction outlet. To remove the canister, pull it out to the rear and off the outlet

Emptying:

The dust canister should be emptied after every 5 minutes of sanding. Remove canister and shake out debris over a trash can.

Hints for optimum use

- Do not place your hands over the ventilation slots.

- Do not exert too much pressure on the tool.

- Regularly check the condition of the sanding sheet. Replace when necessary.

- Always sand with the grain of the wood.

- When sanding new layers of paint before applying another layer, use extra fine grit.

- On very uneven surfaces, or when removing layers of paint, start with a coarse grit. On other surfaces, start with a medium grit. In both cases, gradually change to a fine grit for a smooth finish.

CAUTION: Respiratory hazard. Never operate this tool for wood sanding unless the dust canister is in place. Sanding dust exhaust may create a breathing hazard.

WARNING: Fire hazard. Collected sanding dust from sanding surface coatings (polyurethane, linseed oil, etc.) can self-ignite in sander dust canister or elsewhere and cause fire. To reduce risk, empty canister frequently and strictly follow sander manual and coating manufacturer’s instructions.

WARNING: Fire hazard. When working on metal surfaces, do not use the dust canister because sparks are generated. Wear safety glasses and a dust mask

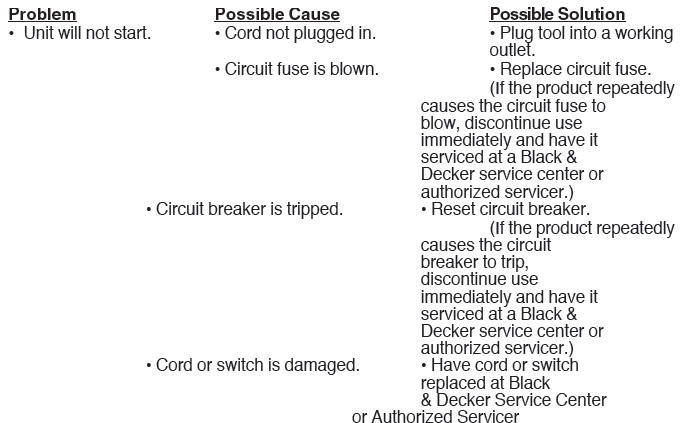

Troubleshooting

Maintenance

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment should be performed by authorized service centers or other qualified service organizations, always using identical replacement parts.

Accessories

Recommended accessories for use with your tool are available from your local dealer or authorized service center. If you need assistance regarding accessories, please call: 1-800-544-6986.

WARNING: The use of any accessory not recommended for use with this tool could be hazardous.

Service Information

All B lack & Decker Service Centers are staffed with trained personnel to provide customers with efficient and reliable power tool service. Whether you need technical advice, repair, or genuine factory replacement parts, contact the B lack & Decker location nearest you. To find your local service location, refer to the yellow page directory under “Tools—Electric” or call: 1-800-544-6986 or visit www.blackanddecker.com

Warranty

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or workmanship. The defective product will be replaced or repaired at no charge in either of two ways. The first, which will result in exchanges only, is to return the product to the retailer from whom it was purchased (provided that the store is a participating retailer). Returns should be made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the sale). Proof of purchase may be required. Please check with the retailer for their specific return policy regarding returns that are beyond the time set for exchanges. The second option is to take or send the product (prepaid) to a B lack & Decker owned or authorized Service Center for repair or replacement at our option. Proof of purchase may be required. B lack & Decker owned and authorized Service Centers are listed under “Tools- Electric” in the yellow pages of the phone directory and available on our website www.blackanddecker.com. This warranty does not apply to accessories. This warranty gives you specific legal rights and you may have other rights which vary from state to state. Should you have any questions, contact the manager of your nearest B lack & Decker Service Center. This product is not intended for commercial use.

Free Warning Label Replacement: If your warning labels become illegible or are missing, call 1-800-544-6986 for a free replacement.st B lack & Decker Service Center

For assistance with your product, visit our website www.blackanddecker.com for the location of the service center nearest you or call the B LACK & DECKER help line at 1-800-544-6986.

Black & Decker QS900 Palm Grip Sander Instruction manual

FAQs

What is the QS900 sander’s power rating?

With its 1.5-amp motor, it has enough power for the majority of sanding jobs.

Can curved surfaces be sanded with the QS900?

Yes, it is perfect for sanding curved or complex surfaces because of its small size and palm grip.

Is there a dust collection system on the QS900?

Yes, it comes with a dust bag and a dust collection mechanism to assist you maintain a clean workstation.

Which kind of sanding pads are used with the QS900?

It makes use of common, easily accessible 5-inch hook-and-loop sanding pads.

Is there variable speed control on the QS900?

Yes, you may change the speed from 7,000 to 12,000 orbits per minute (OPM) thanks to its variable speed control capability.